- Home

- Mevotech Hub Assemblies

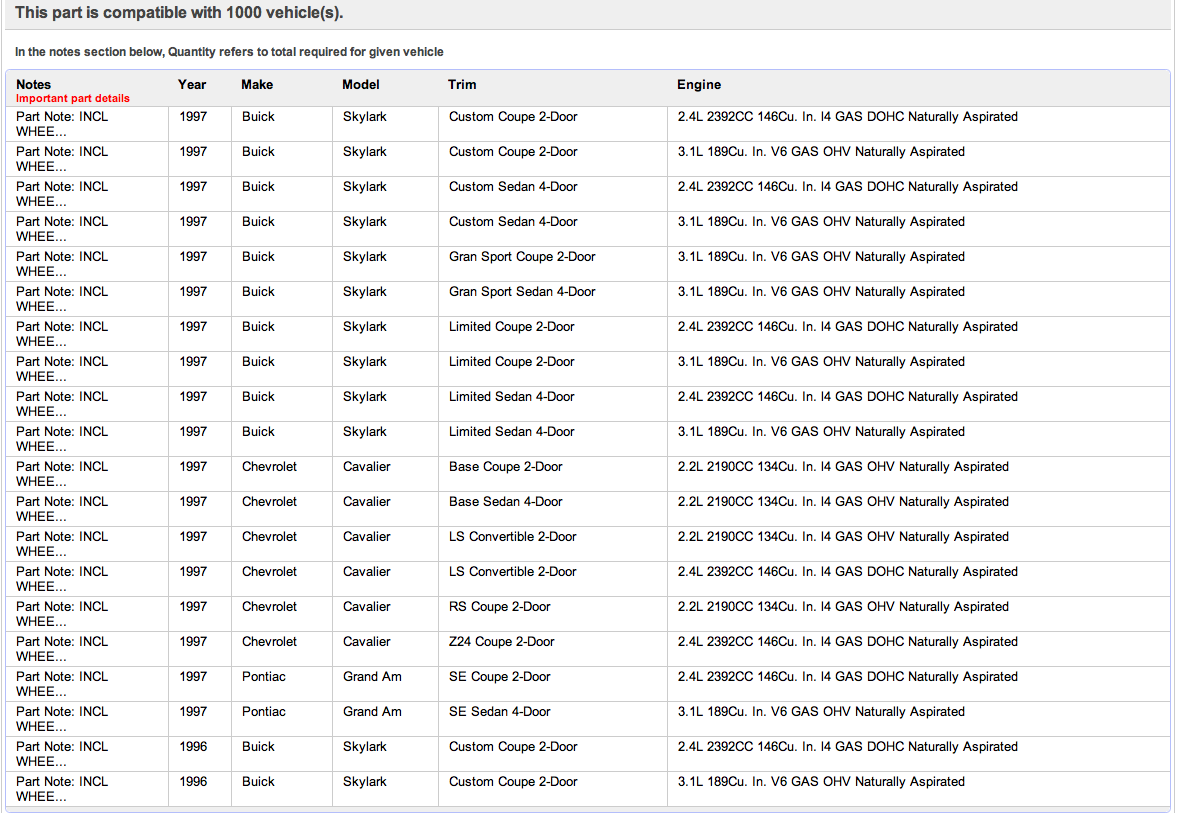

- Mevotech Axle Hub Assembly H513017K

Product Description

Types

Driven – Driven hub assemblies are required to transmit rotational torque to propel the vehicle. Driven hub assemblies are only found on Wheel End’s that are driving. An example would be for a front wheel drive (FWD) vehicle the engine drives the front wheel only, and in this case only the front hub assembly will be a driven type hub assembly.

Non Driven – Non-driven hub assemblies are attached to all the wheel ends that do not required to transmit rotational torque. For a rear wheel drive (RWD) vehicle the front wheels are not driven because the vehicle is propelled by the rear wheels only.

Generations

Generation 1 - First generation wheel bearings are used on many applications due to their compact design, featuring lifetime sealing and lubrication.

Generation 2 - This second generation of hubs is compact, maintenance-free and is not only cost effective but also has an integrated mounting flange. Generation 2 design features a factory-set preload and they are easy to install – bolted directly to spindle.

Generation 3 - Nowadays automotive manufacturers make all the efforts to improve the vehicles handling and performance by reducing their weight and complexity. Generation 3 hub assemblies provide many advantages over previous designs. Once installed, the integrated flanges of the G3 designs allow for low axial run-out and internal bearing integrity will not be compromised.

Purpose

Hub Assemblies and bearings allow the wheel and tire assembly to turn freely around the spindle, in the steering knuckle, or in the bearing support. They are also designed to handle combinations of radial and axial thrust loads Mevotech Wheel bearings are lubricated with high pressure, high-temperature grease. This allows the bearing to operate with very little friction and wear. A hub unit bearing is pre-set, pre-lubricated, sealed and requires no maintenance.

Loading... Please wait...

Loading... Please wait...